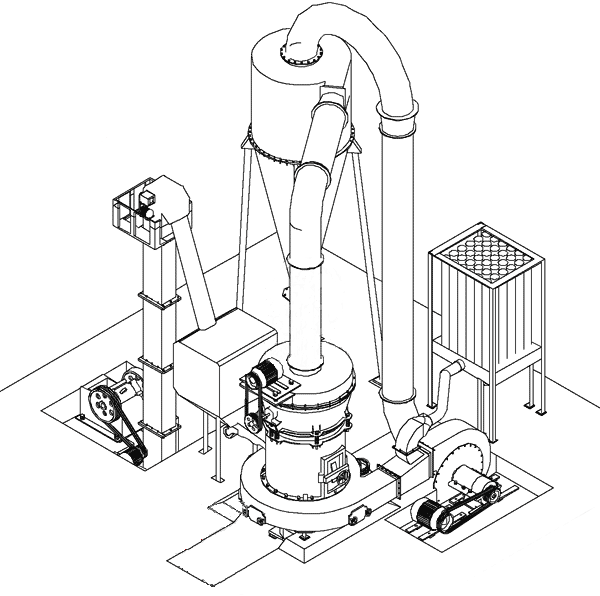

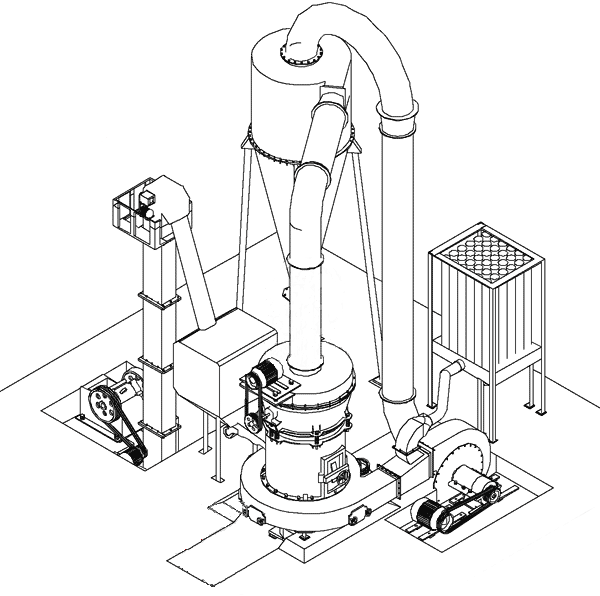

Mtm100 High Pressure Grinding Mill Machine For Calcium Carbonate

MTM Medium-speed Grinding Mill is a world leading tool for powder

grinding. MTM grinding mill absorbs world first-class industrial

powder milling technology and organizes the technical experts and

related engineers for elaborate design, test and improvement.

Product Features: Low energy consumption,high yielding and high

gains

Input Size: 0-35mm

Capacity: 3-22TPH

Material: Limestone, calcite, dolomite, petroleum coal, gypsum,

barite, marble, talc, coal powder, etc.

Inheritance Of Classical Design, Innovation Of Science & Technology

MTM Medium-speed Grinding Mill adopts the classical pendulum

rollers of Raymond Mill on the one hand and change the spring

connection structure innovatively on the other hand, which can not

only avoid the terrible impact of large materials on the axis and

bearings, but also enhance the crushing strength of grinding

rollers so as to increase the yielding.

Lower Electricity Consumption, Higher Economic Profits

Under an ideal circumstance, MTM Medium-speed Grinding Mill

consumes 1.02kW/h when yielding a ton of materials and 1.48kW/h

when feeding a ton of materials. Its electricity consumption is

lower than that of ball grinding mill of the same level by over

60%.

Impeller-Type Energy-Saving Fan Having Higher Efficiency

adopts the high-efficiency impeller energy-saving fan, and the

working efficiency of which can reach 85% or above while

traditional grinding mills equipped with straight blade fan can

reach only 62% of air inducing efficiency. Under the equivalent

production requirements, MTM Medium-speed Grinding Mill can realize

better powder separating and lower power consumption.

Lower Energy Consumption - Cambered Air Duct

MTM Medium-speed Grinding Mill uses the cambered air duct with low

resistance. By this, air flow enters the grinding mill

tangentially. Compared with traditional straight air ducts, the

inlet of this air duct is smooth with little resistance and the

outlet is easy for the dispersing of materials which can avoid

material piling, effectively reducing energy consumption of the

system.

Working Principle

After jaw crushers break large bulky materials to smaller ones,

elevators work to send materials to the hopper. Then, by

electromagnetic vibrating feeders, broken materials are evenly and

quantitatively sent to the grinding chamber of MTM Medium-speed

Grinding Mill. After grinding, materials are blown away by airflow

to the powder concentrator for classifying. Under the action of the

impeller of powder selector, materials which fail to meet fineness

would be sent back to grinding chamber to get another grinding

while qualified powders would be collected by cyclone powder

collector and discharged from the bottom as finished products. And,

after that, the airflow would go into the fan along with the air

return duct at the top of cyclone power collector. This system

adopts a closed circuit and runs under positive and negative

pressure. Because materials have a certain content of moisture,

heat generated during grinding may lead air evaporation or swell in

the grinding chamber so that the amount of airflow increases

sharply. Besides, if the feed port and joints of pipelines are not

sealed well, external air may intrude the grinding mill and lead

imbalance of airflow. So, arranges exhaust valves at the air outlet

of the fan to induce redundant air into the bag filter. After

purifying, the redundant air is discharged. This arrangement can

achieve both the balance of airflow and the eco-friendly

production.

Name | MTM100 |

Ring roll number(pcs) | 4 |

Major diameter of roller(mm) | Φ310X170 |

Inner diameter of roller(mm) | Φ950X170 |

Revolving Speed(rmin) | 130 |

Max feed size(mm) | <25 |

Final size(mm) | 1.6-0.045 |

fineness can reach to 0.038 |

Output(th) | 3-8 |

Main unit motor | Power(kw) | 37 |

Centrifugal induced draft fan motor | Power(kw) | 37 |

Classifier speed regulating motor | Power(kw) | 5.5 |

Elevator | Elevator model | TH210 |

Power(kw) | 3 |

Jaw Crusher | Jaw Crusher Model | PE200×350 |

Power(kw) | 7.5 |

Magnetic vibrating feeder | Main unit motor | GZ2F |

Power(kw) | 0.15 |

Q1: Our Advantage

A: * OEM & ODM Support

* Support Technical Service , Installation , Training , After-Sale

Service.

* Factory Sale Price.

* We have exported to more than 70 countries.

Q2: What's your Delivery Time ?

A: 5-7 days for single machines , 15-20 days for production line.

Q3: Why choose your factory?

A: * Our products are manufactured strictly according to national

and international standard, and we take a test on every grinder

before delivered out.

* We are professional manufacture providing factory price for you.

* we have a professional installation and after-sales staffs.

Q4: How to visit your factory ?

A: * Taking the plane to Zhengzhou International Airport .

* Taking the high-speed rail to Zhengzhou Station .

We also provide free hotel booking and airport pick up service .

Packing & Shipping

1) All the wear out spare parts are packed by plastic films and

wooden boxes.

2) Wire cables are used for fastening the machines.

3) FCL: Shipping by standard exporting container.

4) LCL: Poly wood case.

Looking forward to cooperate with you !